Contract manufacturing

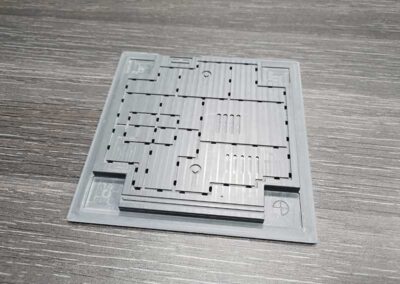

We offer you our machinery as an extended workbench. Daub CNC Technik manufactures workpieces made of aluminum and plastic quickly and easily. The production of single parts up to large series from extruded profiles with max. Length of 6000 mm and metal sheets up to 2000 x 3000 mm are our strength.

HSC (High-Speed-Cutting) milling on our 3-axis portal milling machines with a possible speed of 60000 rpm enables us to provide economical machining of the highest quality. With this form of machining, even the smallest contours or engravings can be produced. We consistently use the latest technologies with our CAD systems for data preparation and CAM for programming. Vacuum clamping technology allows us to produce filigree sheet metal work such as milled pockets, countersinks, chamfers, radii and threads without deformation and without changing the structure of the base material.

Our extensive aluminum stock allows us a short response and manufacturing time of your products.

Likewise, you can provide us with your material with your individual specifications for processing.

We are your contact for contract manufacturing of sheet metal milled parts – from prototypes to series.

For manufacturing we need 2D DXF data or 3D Step data.

Manufacturing capabilities

Screen printing

We screen print according to your specifications in RAL, Pantone or HKS shades.

Our modern screen printer of the company ESC in connection with high quality printing inks guarantees an optimal printing quality on a max. Area from 700x600mm

Advantages in screen printing

– A high opacity

– Durable and extremely hard-wearing print results

– Predestined for high print runs

– High color brilliance

– suitable for light colors on dark backgrounds

Screen printing is a printing process in which the printing ink is printed with a rubber squeegee, through a fine-mesh textile screen onto the material to be printed. At the ink-tight areas of the fabric where no ink is to be printed, the mesh openings of the fabric are closed ink-tight by a stencil.

Digital printing

Unlike screen printing, digital printing does not require a fixed printing plate. Digital printing also known as NIP (Non Impact Printing) or DDP (Direct Digital Printing), is an inexpensive and time-saving printing process. Small print runs can be implemented with artwork directly from the computer without any intermediate steps.

Laser marking

Limitless design possibilities with laser marking. A particularly fast, flexible and abrasion-resistant process for the customized surface design of aluminum without additional tooling costs, additives and solvents.

Press-fit technology with press-fit connectors

Press-in fasteners are pressed into core holes of the workpiece. The material flows by cold forming into an undercut in the shank area of the fastener. Serration or a special head shape prevent the fastener from twisting.

In doing so, they ensure strong mounting points and high push-out and twisting forces without damaging the material or causing bulges in the edge area. The fasteners close flush on the back of the materials.

Press-fit connections are reliable, durable and economical.

Passivation of aluminum

We offer our customers passivation of aluminum plates and piece profiles. The chromate layer produced provides optimum corrosion protection and is a good adhesion base for further coatings.

This coating provides optimum corrosion protection and at the same time serves as an adhesion primer for adhesives, paints and powder coatings in further processing. In addition, it has a low electrical surface resistance, with which low contact resistances are achieved during contacting. To obtain a uniform surface, aluminum plates are degreased and pickled in advance.

Sandblasting/ glass bead blasting

The principle of glass bead blasting is the same as sand blasting. Due to the round shape of the abrasive, the surface is less roughened and obtains a silky glossy and homogeneous appearance. Drawing strips of extruded profiles are completely laminated.

The actual effect of glass bead blasting is created by the “impact” of the beads on the surface. Due to the spherical shape, there is very little or no erosion on the surface. At the same time, the surface thickens and solidifies, providing an optimal pretreatment for anodizing.